Erosion Control Toolbox: Rolled Erosion Control Product Flap With Brush Layering

Introduction

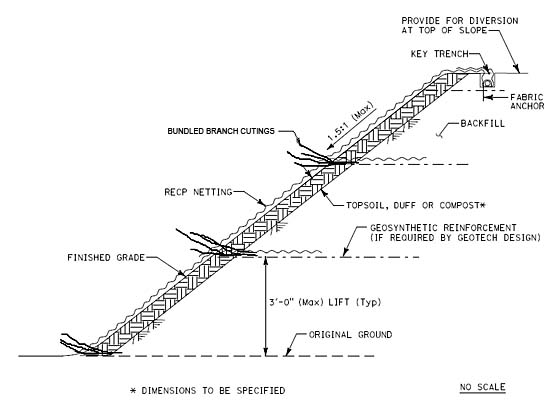

This treatment uses locally obtained green cuttings, a Rolled Erosion Control Product such as coir netting, structural backfill material and local topsoil to construct embankment (fill) slopes. More specifically, this treatment consists of placing layers of:

- Geosynthetic reinforcement - typically placed 2' on center vertically

- Backfill - typically structural material

- Rolled Erosion Control Product - coir/coconut blankets placed every other geosynthetic layer or 4' on center vertically, which "flap over" and protect the slope face

- Local topsoil or compost to provide a rooting media for cuttings

- Green locally harvested cuttings of cottonwood or willow

When to Use This Treatment

- Use to construct embarkment (fill) or reconstructed cut slopes between 2:1 and 1.5:1 (H:V).

- Coordinate the use of this technique with Caltrans Division of Engineering Services (DES) Office of Geotechnical Services, which may prepare a Geotechnical Design Report for slopes greater than 2:1 (H:V).

Consider Using With

How is This Treatment Constructed

- Structural backfill is placed in 8-inch lifts, and "keyed-in" to the adjacent existing slope at least 6.5 feet horizontally. Lifts of backfill are compacted to 90% by track-mounted crawlers.

- A geosynthetic reinforcement layer is placed horizontally between structural backfill lifts, typically every 2' on-center vertically.

- Following placement of the first geosynthetic reinforcement layer (and at every other primary geosynthetic reinforcement layer thereafter) coir netting is placed and fastened longitudinally with fabric anchors.

- A layer of local topsoil and compost is placed on top of the coir netting.

- A layer of green locally harvested cuttings is placed on top of the local topsoil and compost growth media.

- Placement of structural backfill and geosynthetic reinforcement continues in layers, like a cake. At every other geosynthetic reinforcement layer, typically every 4' on-center, coir netting is draped or flapped over the slope face, and a layer of harvested cuttings, topsoil, and compost is placed.

Note: This typical section is schematic only and is not to be used in a contract document. The scale, key dimensions, and critical details have been intentionally omitted.

Benefits

- Provides immediate slope reinforcement with unrooted brush cuttings and horizontal geotextiles. As roots develop, slope stability and shear resistance are improved by creating a rooting matrix with geogrids throughout structural lifts.

- Cuttings create slope breaks that shorten slope length and reduce stormwater runoff velocities.

- Promotes vegetation establishment, cover, and natural recruitment.

- This treatment does not require wrapping the backfill, and is less labor intensive to construct than RECP Wrap.

- Provides the resistive force necessary to hold the soil firmly in place in lieu of compaction by trackwalking.

- The slope face is stabilized and protected from storm events as the embankment is constructed, therefore construction may resume immediately after rainfall.

- Yields a stable and aesthetically pleasing slope compatible with its natural surroundings.

- Promotes vegetation establishment and natural succession.

Limitations

- Unsuitable for embankment (fill) slopes steeper than 1.5:1 (H:V), or slopes with limited access.

- Requires accessible, local stand of cottonwoods or willows from which to harvest cuttings.

- May require supplemental irrigation during establishment period, particularly during the first dry season and on south-facing slopes.

Technical Design Tips

- Always protect the face of embankment (fill) slopes steeper than 2:1 (H:V) to prevent slumping of soil from between horizontal geotextile layers.

- Consider covering (flapping) the face of 2:1 (H:V) embankment (fill) slope faces, based upon evaluation of constraints to compaction, angle of repose, backfill material, and rainfall intensities.

- Backfill lifts typically range from 2 - 4 feet thick. Consider specifying Local Topsoil in the outer face of structural backfill lifts.

- Fill slopes steeper than 2:1 (H:V) typically require reinforcement by a geosynthetic fabric such as a geogrid. Geosynthetic reinforcement strength needs to be sufficient to meet slope engineering requirements and should be specified by a geotechnical engineer.

- Consider the benefits and liabilities of natural geosynthetic products versus longer lasting inorganic (plastic) products.

Updated: February 1, 2019