Erosion Control Toolbox: Wire Mesh Confinement System

Introduction

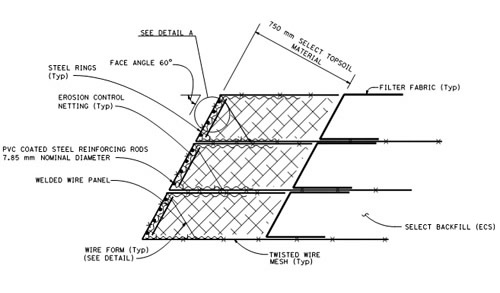

Slopes steeper than 1:1 (H:V) will not reliably support vegetation and require a more permanent confinement technique than Rolled Erosion Control Products (RECP). A wire mesh confinement system provides additional shear strength necessary to hold non-vegetated fill material in place. Key features include:

- Structural backfill material is placed in a double twisted wire mesh enclosure with an articulated front face that can be set to match the desired slope angle

- The bottom of the confinement system can function as a geosynthetic reinforcement layer which enhances slope stability

- Local Topsoil or select material is typically used at the slope to support sustainable vegetative growth

- Rolled Erosion Control Product (RECP) Netting is placed inside the confinement system to prevent release of topsoil through the face

- Welded Wire Confinement System is also known as Embankment Confinement System

When to Use This Treatment

- Fill or reconstructed cut slopes that are between 1.5:1 (H:V) and 0.5:1 (H:V).

- Coordinate the use of this treatment with the Division of Engineering Services (DES) Office of Geotechnical Services, which may prepare a Geotechnical Design Report for slopes greater than 2:1 (H:V)

Benefits

- Provides immediate slope reinforcement

- Creates slope breaks that shorten slope length and reduce runoff velocities

- Increases infiltration rates on dry sites

- Provides for vegetation establishment, cover, and natural recruitment

Limitations

- Unsuitable for slopes with limited equipment access

- Must have solid footing

Technical Design Tips

- Establishment of vegetation is difficult on slopes steeper than 1:1 (H:V), and extremely difficult on slopes that exceed 0.5:1 (H:V)

- Maximum slope gradient of 0.5:1 (H:V) has been used in extreme cases for slope tie-ins to natural grades

Consider Using With

To effectively treat sites with poor soils (compacted, sterile or poorly draining), consider combining this treatment with:

Plans and Details

- Nonstandard Detail - Erosion Control (Wire Mesh Confinement)

Updated: February 12, 2019