Flexible Pavement Recycling

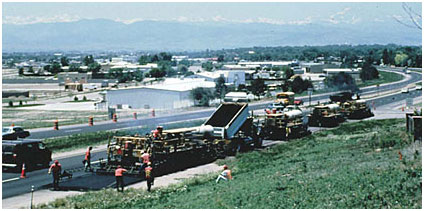

Hot In-Place Recycling (HIPR)

Hot In-Place Recycling (HIPR) is an on-grade method of pavement surface preservation that consists of softening the existing asphalt pavement with heat, milling or scarifying to a maximum depth of 2 inches, and thoroughly remixing, leveling, and compacting the milled or scarified material. HIPR can include the addition of recycling agents and virgin hot mix asphalt (admix) as needed.

Cold In-Place Recycling (CIPR)

Cold In-Place Recycling (CIPR) is an on-grade method of pavement rehabilitation that consists of milling the existing asphalt concrete pavement to a depth between 2 to 4 inches; mixing the cold milled material with emulsified recycling agent and other additives as needed; spreading and compacting the recycled mixture; and overlaying the recycled surface with a new lawyer of hot mix asphalt (HMA). Foamed asphalt can be used as a recycling agent instead of asphalt emulsion, but the fine aggregates may need to be added to the recycled mixture.

Pulverization

Pulverization is an on-grade method of pavement rehabilitation that consists of pulverizing the existing asphalt concrete pavement and a portion of the underlying granular base to a maximum depth of 10 inches, grading and compacting the recycled mixture, and overlaying the recycled surface with a new layer of hot mix asphalt (HMA). Other materials including aggregate base, Portland cement, kiln dust, or fly ash may be added prior to mixing as needed.

For more information visit Concrete Pavements.