Chapter 7: Environmental Stewardship, Section 1: Environmental Rules and Requirements

- 7-101 General

- 7-102 Environmental Commitments Record

- 7-103 Protection of Environmental Resources

- 7-103A Biological Resources and Species Protection

- 7-103B Environmentally Sensitive Area

- 7-103C Cultural Resources

- 7-103D Community Effects and Environmental Justice

- 7-103E Native American Concerns

- 7-103F Aesthetics

- 7-103G Paleontological Resources

- 7-103H Disposal, Staging, and Borrow Sites

- 7-103I Other Contractor Uses of the State Right-of-Way

- 7-104 Air, Water, and Noise Pollution Control

- 7-105 Permits, Licenses, Agreements, and Certifications

- 7-105A Special Use Permits and Other Federal Permits

- 7-105B California Fish and Game Code Sections 1602 and 5650

- 7-105C List of Potential Permits, Licenses, Agreements, and Certifications

- Table 7-1.1. State and Local Agency Permits, Licenses, Agreements, and Certifications (1 of 3)

- Table 7-1.1. State and Local Agency Permits, Licenses, Agreements, and Certifications (2 of 3)

- Table 7-1.1. State and Local Agency Permits, Licenses, Agreements, and Certifications (3 of 3)

- Table 7-1.2. Federal Agency Permits, Licenses, Agreements, and Certifications (1 of 2)

- Table 7-1.2. Federal Agency Permits, Licenses, Agreements, and Certifications (2 of 2)

- 7-106 Hazardous Materials

- 7-107 Hazardous Waste and Contamination

- 7-107A Contractor-Generated Hazardous Waste Versus Caltrans-Generated Hazardous Waste

- 7-107B Aerially Deposited Lead

- 7-107C Naturally Occurring Asbestos

- 7-107D Caltrans-Generated Contaminated Soil

- 7-107E Removing Yellow Traffic Stripe and Pavement Marking with Hazardous Waste Residue

- 7-107F Disturbance of Existing Paint Systems on Bridge

- 7-107G Treated Wood Waste

- 7-107H Disposal of Electrical Equipment Requiring Special Handling

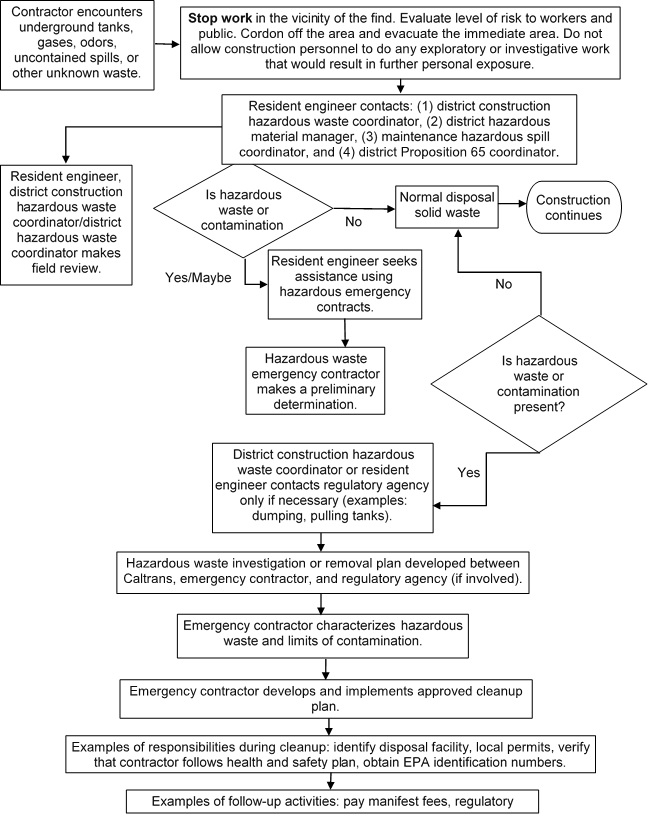

- 7-107I Unanticipated Discovery of Hazardous Waste and Contamination

- 7-108 Crumb Rubber Usage Reporting

- 7-109 Solid Waste Disposal and Recycling Reporting

- 7-110 Certificate of Environmental Compliance

Section 1 Environmental Rules and Requirements

7-101 General

This section provides information and guidelines for administering the various environmental requirements for Caltrans construction contracts.

The district Construction deputy director is responsible for ensuring that environmental permit, license, agreement, and certification (PLAC) requirements are enforced. Within district Construction, stormwater coordinators are appointed. Within either the district environmental or district Construction Unit, environmental construction liaisons are appointed. The environmental construction liaisons must have appropriate training, background, and experience to facilitate effective communications necessary to carry out the responsibilities of both district Construction and the district Environmental Unit. To meet legal requirements, district Construction staff must coordinate and communicate with environmental staff, possess appropriate skills, receive appropriate training, and understand their role in successfully carrying out environmental commitments, including PLACs, within the contract requirements.

7-102 Environmental Commitments Record

Caltrans established the environmental commitments record (ECR) in a memo dated June 5, 2005, from the chief engineer to assure that Caltrans meets its environmental commitments for each project by:

- Documenting all environmental commitments including PLACs.

- Specifying how each commitment will be met.

- Documenting the completion of each commitment.

The ECR contains all relevant environmental compliance information and PLAC requirements; basic project information, including each environmental commitment, person, or unit responsible for commitment completion; timing and manner of implementation; location; and a commitment reference document and other commitment requirements. The ECR is part of the resident engineer’s pending file and is necessary to oversee and track the project environmental commitments. It is used to prepare the Certificate of Environmental Compliance (CEC) during contract acceptance.

The resident engineer will review the ECR with the environmental construction liaison or district Environmental Unit during the preconstruction meeting with Caltrans personnel before meeting with the contractor. The environmental construction liaison or district Environmental Unit can assist with discussing the requirements at the preconstruction meeting. The resident engineer monitors the progress of all construction-related environmental commitments on an ongoing basis throughout the life of the contract and verifies their implementation. Commitments completed during construction should be tracked on the ECR.

The following are necessary for meeting environmental commitments during construction as required by Caltrans policy and law. Refer to Sections 7-103 through 7-109 of this manual for additional requirements specific to:

- Environmental resources

- Air, noise, and water pollution control

- Permits, licenses, agreements, and certifications (PLACs)

- Hazardous materials

- Hazardous waste and contamination

- Crumb rubber usage reporting

- Solid waste disposal and recycling reporting

7-102A Resident Engineer Responsibilities

The resident engineer uses all available assistance and expertise to understand and meet the commitments listed in the ECR. This assistance may come from the environmental construction liaison, stormwater coordinators, project biologist, or other functional areas in the district or region, such as design, cultural resources, hazardous waste, paleontology, hydraulics, or the public information office.

Before work begins, the resident engineer must do the following:

- Verify that the resident engineer’s pending file contains the ECR. An ECR is required for every project; if it is missing, contact the project engineer to obtain it.

- Review the resident engineer’s pending file, ECR, PLACs, construction contract, and Sections 13, “Water Pollution Control,” and 14, “Environmental Stewardship,” of the Standard Specifications for commitments.

- Identify notices, required approvals, and actions necessary to meet regulatory requirements and stewardship goals.

- Meet with the environmental construction liaison, district Construction stormwater coordinator, project biologist, and appropriate environmental and engineering experts in the district to share a full understanding of the contract requirements and commitments listed in the ECR.

- Depending on the project’s size and complexity, an additional preconstruction meeting may be used exclusively for discussing environmental commitments and requirements.

- Review Sections 10-1.03, “Time Constraints,” 13, “Water Pollution Control,” and 14, “Environmental Stewardship,” of the Standard Specifications and the special provisions for water pollution control and environmental time constraints. Make sure those time constraints are reflected in the critical path method baseline schedule, including submittal review times.

During the course of work, the resident engineer must do the following:

- Periodically meet with the environmental construction liaison to review the ECR and confirm that environmental commitments required by the contract will be met.

- Inspect the contractor’s operations for compliance with the specifications and the PLACs.

- Before submitting a change order or an authorization to proceed with change order work, review the change order work with the environmental construction liaison to confirm that the proposed change does not adversely affect environmental commitments.

- Verify that the contractor notifies and obtains the resident engineer’s approval in advance for each new activity as required. Check that the contractor’s schedule is coordinated with necessary environmental activities.

- Direct the contractor to correct any identified deficiencies in environmental compliance efforts.

- Should noncompliance occur, initiate contractual enforcement procedures appropriate to the nature and severity of the situation.

Before accepting the contract, the resident engineer must do the following:

- Verify that all environmental commitments required by the PLACs and by the contract have been met.

- Require the contractor to remove temporary best management practices (BMP) measures, such as environmentally sensitive area (ESA) fences or other measures unless the BMP measures are part of permanent measures or requested to be left in place by the district Maintenance Unit.

- Conduct a final walk-through of the project area with the environmental construction liaison.

7-103 Protection of Environmental Resources

This section contains guidelines for protecting and preserving environmental resources, such as biological, cultural, Native American, or paleontological items, and administering the contract’s environmental resource requirements during construction as required by Caltrans policy and law.

7-103A Biological Resources and Species Protection

Both state and federal laws protect designated plant and animal species and their respective habitats. Strict prohibitions exist on certain types of work, work during certain times of the year, or work at specific locations. Even inadvertently affecting protected species can result in fines or jail sentences and may result in significant project delays. The PLACs and species protection measures in the contract will specify the necessary protection measures and restrictions, and the plans will show ESAs. However, during construction, project staff or personnel from regulatory agencies may discover protected species that were not anticipated in the contract. If such a discovery occurs, suspend work in the area and immediately notify the environmental construction liaison, project biologist, or district Environmental Unit.

The U.S. Migratory Bird Treaty Act and the California Fish and Game Code make it illegal to harm migratory birds, nongame birds, and their occupied nests. Activities that are most likely to encounter migratory birds, nongame birds, and their occupied nests include clearing and grubbing; and bridge demolition, maintenance, and retrofit work. Bird protection is a subset of species protection. Species protection responsibilities apply to bird protection. PLACs and the bird protection or species protection measures in the contract will specify the necessary protection measures and restrictions, and the plans will show any ESAs.

When occupied nests are found within the project area, the resident engineer will evaluate, with the assistance of the environmental construction liaison or project biologist, whether work in the area can continue or if suspension of work is necessary. The resident engineer will immediately contact the environmental construction liaison or district Environmental Unit for assistance in this evaluation.

7-103A (1) Resident Engineer Responsibilities

The resident engineer uses all available assistance and expertise to protect natural resources. This assistance may come from the environmental construction liaison, contractor-supplied biologist, project biologist or other state-furnished biologist, or other functional areas in the district, such as design, cultural resources, stormwater, hazardous waste, paleontology, and hydraulics.

Before work begins, the resident engineer must do the following:

- When the contract specifies a contractor-supplied biologist, regulatory agency approvals may be required before accepting the contractor-supplied biologist. Do not accept submittals from the contractor-supplied biologist until approval is obtained. Understand that a contractor-supplied biologist works for the contractor and does not speak for Caltrans.

- Meet with the environmental construction liaison, project biologist, and appropriate environmental and engineering experts in the district to share a full understanding of the contract requirements for species and natural resource protection.

- If an ECR-required Biological Resource Information Program (BRIP) has been prepared by Caltrans, supply a copy to the contractor. If the specifications require the contractor to prepare a BRIP, coordinate a review with the environmental construction liaison or project biologist. Only accept the BRIP if it complies with the PLACs and provisions of the contract.

- If there is a bid item for a natural resource protection plan, Section 14-6.03D(2), “Natural Resource Protection Plan,” of the Standard Specifications will apply. Coordinate review of the contractor’s natural resource protection plan with the environmental construction liaison or project biologist. Note that the specifications prohibit any work that has the potential to adversely affect protected species and their habitat without permission from regulatory agencies.

- Before earthwork or clearing and grubbing begins, request that required preconstruction biological surveys be completed and results be provided to understand regulatory requirements that may delay activities.

- When work occurs in water, or where vibrations or sounds from construction or other project-related activities may pass into waters, review hydroacoustic requirements for the protection of water-dependent species and assure that necessary protections, approvals, monitoring activities, and reports are complete or active as required.

- Designate appropriate staff to assist in preventing adverse effects to biological resources as needed.

During the course of work, the resident engineer must do the following:

- If required by the specifications or PLACs, maintain a copy of the BRIP on the project site and make sure that staff completes required training.

- Inspect the contractor’s operations for compliance with the specifications and the PLACs, the biological provisions, and the accepted natural resource protection plan, when required.

- Verify that the contractor adheres to the monitoring or survey schedule set forth in the PLACs, the biological provisions, and the accepted natural resource protection plan, and provides written reports of these inspections on schedule.

- Verify that the contractor maintains species protection measures so that they will function as planned.

- Check that the contractor has the necessary staff and materials on hand to inspect and maintain species protection measures.

- Assure that the contractor notifies and obtains the resident engineer’s approval in advance for each new activity, as required. Make sure the contractor’s schedule is forwarded to the environmental construction liaison or project biologist and coordinated with necessary resource monitoring.

- Assure that construction does not result in new barriers to aquatic species passage or create issues with maintenance of existing passages.

- Immediately notify the environmental construction liaison and project biologist when protected resources are affected or may be affected by project activities. The project biologist will determine what action is necessary and will advise the resident engineer.

- If necessary, meet with personnel from regulatory agencies, such as the U.S. Fish and Wildlife Service; Environmental Protection Agency (EPA); Army Corps of Engineers; National Oceanographic and Atmospheric Agency, National Marine Fisheries Service; and the California Department of Fish and Wildlife, to discuss protected natural resources and measures to protect resources. The environmental construction liaison or project biologist will assist in discussions and negotiations.

Before accepting the contract, the resident engineer must do the following:

- As required by the PLACs and by the contract, determine that all biological requirements are complete.

- Verify that the project has not maintained or created barriers to aquatic organism passage.

- Conduct a final walk-through of the project area with the project biologist.

7-103A (2) Contractor Inspections

The PLACs and special provisions for species protection may require the contractor to inspect the job site periodically for the proper implementation, performance, and maintenance of species protection measures. The contractor must follow the species protection measures specified in the PLACs, special provisions, and natural resource protection plan, and may be required to report on activities.

If any situation constitutes potential noncompliance with the permit, the resident engineer must conduct a verification inspection, and, if a noncompliant condition exists, report it to the environmental construction liaison or project biologist. The environmental construction liaison or project biologist will coordinate with the district environmental office to determine the actions required, including timely reporting to regulatory agencies and necessary options for compliance. The resident engineer must require the contractor to amend the natural resource protection plan, if necessary, and to install additional species protection measures to achieve compliance.

7-103A (3) Project Files

The resident engineer must keep copies of all applicable documents related to species protection measures as required in PLACs, special provisions, BRIP, and the natural resource protection plan, and retain copies in Category 18, “Agreements,” of the project files. Retain all the required documents for at least 3 years after contract completion, or longer if required in the PLACs. Provide specific disposition instructions in Category 18, “Agreements,” when retention beyond 3 years is required. These documents include the following:

- Periodic reports and photographs related to species protection as required.

- Notification documentation of regulated species as required by PLACs.

- All correspondence related to species protection, including notices of noncompliance.

- Inspection, survey, and monitoring reports supplied by the contractor, environmental construction liaison, or project biologist.

- Inspection reports from the resident engineer and assistant resident engineer.

- Copies of the approvals and certifications required by the specifications.

7-103B Environmentally Sensitive Area

The ESA is shown approximately on the plans and creates a secure area within the plan boundaries enclosed by a temporary fence (Type ESA). The resident engineer should consult with the environmental construction liaison when marking the exact boundaries of the ESA. If the area is breached, immediately secure it, stop all operations within 60 feet of the boundary, and verify that the contractor follows the directions in Section 14-1.02, “Environmentally Sensitive Area,” of the Standard Specifications. The resident engineer will consult with the environmental construction liaison, project biologist, or project cultural specialist before approving entry into an ESA and when identifying or assessing damage. If the ESA is damaged, document the damage and, through consultation with the environmental construction liaison or district Environmental Unit, determine the necessary remediation including the party to perform the remediation work. Take an administrative deduction for the cost of the work when applicable, as covered by Sections 3‑906G, “Deductions,” and 5-103F (1c), “Deductions,” of this manual.

7-103C Cultural Resources

Mitigating a project’s effect on historical and archaeological sites during construction may require the recovery of artifacts. Mitigation may also require Native Americans, archaeologists, architects, and historians to monitor and coordinate the recovery process. Normally, archaeological work is done in advance of construction, but occasionally finds are made during construction. If human remains or previously unknown historic and archaeological artifacts are unearthed, suspend work in the vicinity until the find can be evaluated and properly treated. Seek assistance from the project manager, environmental construction liaison, project cultural specialist, or district Environmental Unit. For more information, refer to the Standard Environmental Reference, Vol. 2, “Cultural Resources.”

7-103D Community Effects and Environmental Justice

Mitigating project effects on communities during construction may require actions in the community. These requirements may be included as part of the contract, including change orders, but they can also be listed as an item on the ECR. Also, refer to Section 8-2, “Equal Employment Opportunity,” of this manual regarding Title VI of the Civil Rights Act of 1964 and environmental justice.

Executive Order 12898, “Federal Actions to Address Environmental Justice in Minority Populations and Low-Income Populations,” directs federal agencies to achieve environmental justice by identifying and addressing disproportionately high and adverse human health and environmental effects, including the interrelated social and economic effects of their programs, policies, and activities on minority and low-income populations in the United States.

7-103E Native American Concerns

These requirements are placed to alleviate concerns of the Native American community. If resources of concern to Native Americans, human remains, or previously unknown associated artifacts are unearthed, suspend work in the vicinity until the concern can be evaluated and properly resolved. Seek assistance from the project manager, environmental construction liaison, project cultural specialist, or district Environmental Unit. For more information, refer to the Standard Environmental Reference, Vol. 2 at:

https://dot.ca.gov/programs/environmental-analysis/standard-environmental-reference-ser

7-103F Aesthetics

Aesthetics are considered during the planning, design, and construction of transportation projects to adequately address a transportation project’s visual effects and to help integrate the facility into the surrounding context. Aesthetic features included in the construction documents are the result of commitments included in the environmental document or made to the community to address scenic, aesthetic, historic, cultural, environmental, and recreational values. The integration and construction of these aesthetic features on a project is critical to fulfilling the aesthetic commitments.

Proposed changes to the plans and specifications that affect the aesthetic features must be coordinated with and approved by the district landscape architect to assure that Caltrans’ aesthetic commitments are accomplished as intended.

7-103G Paleontological Resources

Paleontological resources are evidence of ancient life, not including human life, preserved as fossils in sediments and rock. In geologically diverse California, vertebrate, invertebrate, and plant fossils are found throughout the state. Paleontological resources have unique scientific value and, as a result, must be protected. Refer to Chapter 8, “Paleontology,” of the Standard Environmental Reference Vol. 1, for information about applicable laws.

Paleontological resources may be encountered when a project includes invasive activities such as excavation or drilling of previously undisturbed sediments and rock. If paleontological resources are anticipated, the contract should include special provisions in accordance with Section 14-7, “Paleontological Resources,” of the Standard Specifications. Protection of paleontological resources usually includes preservation of scientific information through monitoring, and fossil and data recovery. This work is normally performed by a consultant working directly for Caltrans, not the construction contractor. In these cases, the resident engineer must assure the coordination and cooperation of the construction contractor with the paleontological consultant. This is accomplished by including the paleontological consultant in preconstruction meetings, providing the paleontological consultant with an accurate and updated schedule of subsurface disturbing activities, and, when required, making sure that the contractor’s staff attends paleontological awareness training presented by the paleontological consultant.

In most cases, paleontological monitoring and fossil and data recovery can be performed with minimal effect on construction activities. However, when large specimens or fossil-rich areas are encountered, excavation activities may need to be temporarily diverted while the paleontological team stabilizes and removes them. In these cases, the resident engineer must facilitate coordination and cooperation between the paleontological monitoring team and the construction contractor.

If unanticipated paleontological resources are encountered, the construction contractor is directed to stop work within a 60-foot radius of the discovery and contact the resident engineer. The resident engineer must contact the environmental construction liaison who will enlist the assistance of the appropriate technical staff to investigate the discovery. Work in the area of discovery cannot resume until the find has been properly evaluated and recovery activities completed as necessary. The remaining construction activities must be evaluated in context of the discovery and monitoring may be required. If monitoring is required, it may be accomplished through either a separate contract (preferred) or a subcontract through the prime construction contractor. In either case, assistance from the environmental construction liaison or district Environmental Unit will be necessary.

After excavation is complete, a paleontological mitigation report will be prepared by the paleontological consultant. After receiving the report, the resident engineer must coordinate with the environmental construction liaison or district Environmental Unit to update the ECR. If fossils are recovered from the project, they will be properly curated. The resident engineer must coordinate with the environmental construction liaison or district Environmental Unit to verify that funding is made available to pay for reporting and curation activities performed by the consultant.

7-103H Disposal, Staging, and Borrow Sites

Caltrans construction projects often require contractors to make use of either state-owned or private off-site lands and facilities for the disposal of excess materials; the acquisition of necessary borrow materials; and to stage equipment, store supplies, and house their offices. Contract documents generally require the contractor to show that construction activities on these sites comply with all local, state, and federal environmental and permitted use regulations. However, in some geographic locations there have been issues regarding final compliance responsibility. To resolve these issues and to foster better cooperation with regulatory agencies, the option of designating disposal, staging, and borrow (DSB) sites has been facilitated.

Construction projects that cannot accommodate the needs of the project within the right-of-way may have designated sites outside the project limits. However, even when such sites are made available, the contractor will continue to have the flexibility of using alternative sites. Alternative sites selected by the contractor require the contractor to prepare a submittal to the resident engineer for approval. Requirements for this submittal are outlined in the following section, and additional guidance is available at the Design Memoranda for Designated Disposal, Staging, and Borrow Sites:

https://dot.ca.gov/programs/design/design-memoranda

The need for identifying and obtaining environmental approvals for a designated DSB site will generally have been made by the project engineer on a case-by-case basis, considering historical and geographical issues and practices, project design requirements, environmental concerns, economic factors, and other aspects specific to projects and their locale. During project development, the project engineer should have considered and identified sites readily available for use by the contractor. These sites would have included, but not be limited to, commercial dumpsites, recycling plants, private property, and other local sites. If it was deemed necessary that one or more DSB sites needed to be designated, the project engineer would have proposed sites evaluated during the environmental review process and, as necessary, included them in the environmental compliance documentation. To assure their availability to the contractor, right-of-way agreements would have been obtained for private sites selected as designated DSB sites. Any necessary permits would have been included among those obtained during the plans, specifications, and estimate development. Information or documents regarding arrangements made by Caltrans to assure the availability of designated sites are provided to prospective bidders or contractors in a materials information handout.

Following are summaries for the minimum items expected in: (1) a DSB site submittal for a site designated by Caltrans; and (2) a summary of the minimum items expected in a DSB site submittal for a contractor to get approval for the use of an alternate site. File submittal and support documents in the project files.

7-103H (1) Caltrans- and Contractor-Designated Disposal, Staging, and Borrow Sites

For Caltrans-designated sites Caltrans will:

- Provide a general site plan, including site limits and access roads.

- Obtain temporary property owner agreements as necessary to “reserve” property.

- Prepare California Environmental Quality Act or National Environmental Policy Act documentation, as needed, in consultation with the Environmental Unit.

- Verify the existence of or obtain the necessary PLACs to satisfy regulatory agencies and assure site availability in consultation with the Environmental Unit.

- Review and accept the contractor’s submittal.

For Caltrans-designated sites the contractor will:

- Prepare a final grading plan in conformance with the Standard Specifications.

- Provide a release of liability.

- Provide final property owner agreements (refer to Section 3-603, “Local Materials,” of this manual).

- Submit a written plan for water pollution prevention in conformance with the Standard Specifications.

For alternative sites selected by the contractor:

- Caltrans will review and accept the contractor’s submittal.

- The contractor will:

- For borrow sites, demonstrate that the site is either not subject to or is in compliance with the Surface Mining and Reclamation Act (SMARA). If the borrow site is not subject to SMARA, confer with the environmental construction liaison or district Environmental Unit to assure that the borrow site is not a potential contamination source.

- For all DSB sites:

- Provide a site plan, including site limits and access roads.

- Obtain and provide property owner agreements; refer to Section 3-603, “Local Materials,” of this manual.

- Provide a release of liability.

- Provide environmental documentation prepared by appropriately qualified environmental specialists.

- Obtain or update all necessary PLACs.

- Determine the final grading plan in conformance with the Standard Specifications.

- Submit a written plan for water pollution prevention in conformance with the Standard Specifications.

7-103H (2) Surface Mining and Reclamation Act

Section 10295.5 of the Public Contract Code requires that Caltrans buy or accept sand, gravel, aggregates, or other mined materials, including imported borrow, from mining operations that are in compliance with or not subject to SMARA. The resident engineer can use the list of mining operations in compliance with SMARA, also called the “AB 3098 List,” to verify which mining operations are in compliance. The current list may be obtained from the Department of Conservation website:

https://www.conservation.ca.gov/smgb/Pages/Lead-Agency-Resources.aspx

Mining operations that meet the following criteria are not subject to SMARA and are not required to be on the AB 3098 List:

- A total amount of mined materials less than 1,000 cubic yards in any one location of 1 acre or less.

- Onsite excavations and onsite earth-moving activities on a Caltrans construction project that are an integral and necessary part of the project.

- Materials mined from federal lands, except for lands that the Bureau of Land Management and Forest Service regulate.

- Materials mined from tribal lands, when mined by a tribal mining operator.

- Materials mined from outside of California.

Review contractor-proposed sources and verify that the source is on the current AB 3098 List. If the contractor proposes to use mined material from a mining operation not on the AB 3098 List, obtain from the contractor proof that the operation is not subject to SMARA, in accordance with the criteria above, and confirm with the Department of Conservation. Contact the Division of Mine Reclamation, Reporting Unit, at: DMR-Reporting@conservation.ca.gov or (916) 323-9198.

SMARA allows the State Mining and Geology Board to exempt certain mining operations or construction projects. Caltrans can accept material from exempted sources if the contractor provides proof of the board-granted exemption.

If the proposed site is not on the AB 3098 List, and the contractor cannot demonstrate that the site is not subject to SMARA or that an exemption has been granted, the resident engineer must not accept the contractor’s submittal. Refer challenges to the acceptance of materials to the Division of Construction field coordinator.

7-103I Other Contractor Uses of the State Right-of-Way

The contractor’s use of Caltrans-owned parcels that are outside of the project limits will be contingent upon approval by the resident engineer, based on:

- The DSB site submittal.

- Execution of a fair market rental agreement with Caltrans.

- Execution of an encroachment permit by the district permit engineer.

The resident engineer should consult with the project engineer and environmental construction liaison or district Environmental Unit before approving the DSB site submittal. For more information, refer to Section 3-516, “Areas for Use,” of this manual.

7-104 Air, Water, and Noise Pollution Control

This section contains guidelines for administering the contract’s air, water, and noise requirements.

7-104A Air Pollution Control

7-104A (1) Air Quality

Section 7-1.02C, “Emissions Reduction,” of the Standard Specifications states that the contractor, by executing the contract, is aware of California Air Resources Board (ARB) regulations and will comply with those regulations before starting work and throughout the duration of the contract.

The resident engineer does not need to verify that the contractor’s equipment complies with ARB regulations. The local air quality control district or air quality management district, commonly referred to as the “air district,” is responsible for enforcing air quality regulations. If complaints are brought to the resident engineer’s attention, the resident engineer should direct the complainant to file the complaint with the local air district.

If the complaining party insists that Caltrans handle the situation, the resident engineer should forward the complaint to the local air quality control district, based on project location, and send the contractor a copy of the complaint filed.

A list of local air quality control districts, contacts, and addresses is available at:

https://ww2.arb.ca.gov/air-pollution-control-districts

All Caltrans projects must comply with the Clean Air Act. Permits are issued by local air quality management districts and require that the project create no smoke, offensive odors, or visible dust. Contractors must take appropriate measures to make sure their equipment is properly maintained and to apply water and other dust palliatives as frequently as necessary. Violations can result in fines and sanctions against the contractor and Caltrans.

7-104A (2) Dust Control

Under the terms of the project contract, the contractor must control dust. The contractor must maintain such control whether payment is included in the prices paid for the various items of work involved or whether payment is made separately. Refer to Sections 4-10, “General Construction,” and 4-18, “Dust Palliatives,” of this manual for additional guidance related to dust control.

During the preliminary inspection, before work begins, take the following steps:

- Determine whether a planned method to control dust is included in the contractor’s accepted plan for water pollution prevention.

- Whenever it is proposed to handle temporary traffic changes on an unpaved roadway, anticipate the necessity for dust control. Notify and require corrective action whenever the contractor is not adequately controlling dust. In cases of neglect, work may be suspended under the resident engineer’s authority, pursuant to Section 8-1.06, “Suspensions,” of the Standard Specifications.

7-104B Water Pollution Control

To assure control of pollutants in discharges of stormwater runoff, Caltrans construction projects may be subject to federal law under the Clean Water Act and state law under the California Water Code. All Caltrans construction projects are subject to the Caltrans National Pollutant Discharge Elimination System (NPDES) permit issued by the State Water Resources Control Board (SWRCB) and one of the following NPDES permit requirements: the statewide Construction General Permit (CGP) issued by the SWRCB, the Lake Tahoe CGP issued by the Lahonton Regional Water Quality Control Board (RWQCB), or the federal CGP issued by the EPA. The project specifications should identify which permits apply to the project.

For each construction project, the contractor must prepare either a stormwater pollution prevention plan (SWPPP) or a water pollution control program (WPCP) in accordance with Section 13, “Water Pollution Control,” of the Standard Specifications, Caltrans’ Stormwater Quality Handbooks, and the contract’s special provisions. These documents describe the measures the contractor must implement to prevent construction activities from polluting the waters of the United States. The resident engineer must authorize all such preventive measures, and then the contractor’s forces must implement and maintain the measures.

Successfully protecting water resources, such as streams, waterways, and other bodies of water, and protected water-dependent species from pollution is critical to the project’s success. Water resources must be protected from chemical pollutants, including petroleum products, paint residues, and curing compounds, and from sediment in stormwater runoff. Caltrans has developed an evaluation plan to review the contractor’s water pollution control program and to evaluate construction projects for overall adequacy in implementing stormwater pollution prevention measures. The Construction Compliance Evaluation Plan provides a process for evaluating the potential threat to water quality from predicted storm events. The plan also separates water quality compliance from stormwater contract administration.

For projects covered by the statewide or Lake Tahoe CGP, permit registration documents and other permit-related compliance documents must be filed electronically with the SWRCB through the Storm Water Multiple Application and Report Tracking System (SMARTS) at:

https://smarts.waterboards.ca.gov/smarts/faces/SwSmartsLogin.xhtml

All requests to start construction, Notices of Intent, requests for termination of a project, Notices of Termination, and interim reporting are made through SMARTS.

To set up a SMARTS profile, the CGP and SMARTS require establishment of certain responsibilities, including:

- The legally responsible person (LRP)

- The approved signatory

- A data entry person

For Caltrans, the LRP is the district director, although as many as three backups may be designated to perform the same duties, with responsibility for permit compliance and designating the approved signatory for the project. Assignment of an approved signatory is accomplished by the linking process in SMARTS as detailed in the SMARTS User’s Manual. The manual is posted on the Division of Construction Stormwater Training Presentations intranet page.

A project can have more than one approved signatory. The resident engineer is responsible for the project data submitted in SMARTS and must be designated an approved signatory. The LRP may link other approved signatories to the project as necessary to support project delivery. Documentation for SMARTS submittals comes from various members of a project development team; however, the approved signatory is responsible for submitting permit registration documents, the Notice of Intent, discharge reports, annual reports, ad hoc reporting, and Notice of Termination certification.

A data entry person may be any Caltrans staff member or contractor’s personnel designated by the LRP or approved signatory to input information into SMARTS.

The Notice of Intent provides the RWQCBs with details about the project and is a request for coverage under the CGP. The process involves filing project-related information and the project SWPPP. Obtain information necessary to complete the SMARTS Notice of Intent from the project “Storm Water Data Report Attachment for SMARTS Input.”

Reporting in SMARTS is accomplished by entering data into specific tabs or by uploading documents. For example, the Notice of Intent is created by entering data in the fields under the Notice of Intent tab, whereas the project SWPPP and its amendments are uploaded into the system. There are also screens for discharge reporting, annual reports, and other permit-related project reports. The approved signatory may certify submittals in SMARTS and, when applicable, will need to provide the qualified SWPPP developer’s certification. Hard copies of these documents must be maintained in the project files.

Section II.D, “Obtaining and Terminating Permit Coverage,” of the CGP fact sheet details when a project is complete and a Notice of Termination is appropriate. Consult with the project engineer to verify that the conditions have been satisfied. For additional guidance, refer to:

https://www.waterboards.ca.gov/water_issues/programs/stormwater/constpermits.shtml

7-104B (1) District Construction Stormwater Coordinator Responsibilities

District Construction must have at least one designated district Construction stormwater coordinator who will carry out necessary administrative functions to prevent water pollution. This coordinator reviews the contractor’s SWPPP or WPCP, visits projects, and acts as technical advisor to the resident engineer. The coordinator evaluates projects for potential threats to water quality and the effectiveness of stormwater contract administration. The district Construction stormwater coordinator works with other functional areas in the district, assists resident engineers to verify compliance, and assures that field construction personnel are appropriately trained.

7-104B (2) Resident Engineer Responsibilities

The resident engineer uses all available assistance and expertise in preventing water pollution. This assistance may come from the district Construction stormwater coordinator, environmental construction liaison, or other functional areas in the district, such as landscape architecture, environmental analysis, and hydraulics.

Before work begins, the resident engineer must do the following:

- Designate appropriate staff as stormwater inspectors to assist in preventing stormwater pollution.

- Review the construction contract and the resident engineer’s file for instructions and commitments.

- Verify that permit registration documents are submitted into SMARTS.

- Verify that all proper forms have been filed with the RWQCB.

- Meet with the appropriate environmental and engineering experts in the district to assure a full understanding of the contract requirements for water pollution prevention.

- Conduct a preconstruction meeting with the contractor to discuss all required stormwater measures and requirements. Depending on the project’s size and complexity, this preconstruction meeting may be used exclusively for discussing water pollution prevention or the topic may be included in a general preconstruction meeting.

- Provide the contractor with a copy of the district Design Unit’s conceptual SWPPP for the project, if one has been prepared.

- Review and authorize the contractor’s SWPPP or WPCP as required by the specifications. The district construction stormwater coordinator may assist in the review. Note that before the resident engineer has authorized the plan, the specifications prohibit any job site activities. If a RWQCB requires review of the authorized SWPPP, job site activities are prohibited until the board reviews and comments on the authorized SWPPP.

- Before any job site activities begin, make sure the contractor deploys any stormwater measures called for in the SWPPP or WPCP.

During the course of work, the resident engineer must do the following:

- Maintain a copy of the authorized SWPPP or WPCP on the project site.

- Inspect the contractor’s operations for compliance with the specifications and the authorized SWPPP or WPCP, including deployment of best management practices measures.

- Check that the contractor adheres to the inspection schedule set forth in the SWPPP or WPCP and provides written reports of these inspections.

- Verify that the contractor prepares and submits Form CEM-2045, “Rain Event Action Plan,” or Form CEM-2045T “Rain Event Action Plan—Lake Tahoe Hydrologic Unit” if applicable, for risk levels 2 and 3 on SWPPP projects.

- Verify that the contractor prepares and submits project annual reports.

- Check that the contractor deploys stormwater and nonstormwater best management practices measures whenever associated construction activities are taking place.

- Check that the contractor maintains best management practices measures so that they will function as planned.

- Check that the contractor has the necessary materials on hand to deploy any necessary additional measures in the event of a storm.

- Check that the contractor uses appropriate measures to stabilize slopes at the times specified. In accordance with the specifications, verify that the contractor submits an implementation schedule for soil stabilization and sediment control for disturbed soil areas.

- Verify that the contractor complies with any provisions that restrict the size of the contractor’s disturbed soil area.

- Make sure the contractor notifies the resident engineer and obtains the resident engineer’s authorization in advance for each first-time nonstormwater discharge, excluding exempted discharges.

- Monitor the contractor’s active and nonactive disturbed soil areas.

- Verify that the contractor conducts soil stabilizing activities as specified.

- Check that the contractor’s water pollution protection plan addresses avoiding water quality effects from removal of bird nests on bridges and other structures over or near water during pre-nesting seasons.

- Direct the contractor to correct any deficiencies in compliance efforts identified in the contractor’s or district Construction stormwater coordinator’s project evaluation reports.

- If any pollutants are discharged into the waters of the United States, notify the district Construction stormwater coordinator immediately. Review the NPDES permit and Statewide Stormwater Management Plan to determine the appropriate reporting timeframe, and provide a draft report of noncompliance to the district NPDES stormwater coordinator. Unless otherwise indicated in the district or regional work plans, the district NPDES stormwater coordinator will then forward the report to the RWQCB. For SWPPP projects, require the contractor to prepare Form CEM‑2061, “Notice of Discharge Report,” or Form CEM-2061T “Notice of Discharge Report—Lake Tahoe Hydrologic Unit Stormwater Sample Field Test Report/Receiving Water Monitoring Report” if applicable.

- Report to the district Construction stormwater coordinator any illegal discharges or illicit connections. Require the contractor to prepare Form CEM‑2061 or Form CEM-2061T, if applicable, as specified in the SWPPP.

- Should noncompliance occur, initiate contractual enforcement procedures commensurate with the nature and severity of the noncompliance. Contract enforcement may include the following:

- Withholding funds from contract payment as specified in the contract.

- Suspending any work that would exacerbate the noncompliance or interfere with or prevent the contractor’s efforts to correct the deficiency. For example, earthwork operations may be suspended until the contractor controls sediment or stabilizes soil as specified. Other work performed by a crew might be suspended if that crew is needed to install best management practices measures.

- Meet with personnel from regulatory agencies, such as the Environmental Protection Agency, RWQCB, or SWRCB to discuss stormwater issues and measures.

- Verify that the contractor submits an annual certification of compliance, Form CEM‑2070, “SWPPP/WPCP Annual Certification of Compliance,” as specified. Sign, date, and file this certification in the project files.

- At 90 percent construction completion, a field review and completion of Form MTCE-0023, “Construction to Maintenance 90% BMP Completion Walkthrough,” will be conducted with the district Maintenance stormwater coordinator or their designee as the lead and form signatory. Following agreement on the construction status, the Maintenance superintendent or supervisor who assumes responsibility for the maintenance of stormwater elements will join as part of the inspection attendees, assisting the district Maintenance stormwater coordinator with the stormwater element evaluation.

Before accepting the contract, the resident engineer must do the following:

- Determine that all slopes are stabilized, as required by the contract.

- Require the contractor to remove temporary BMP measures that are not a part of permanent erosion control unless the BMP measures are part of permanent measures or requested to be left in place by the district Maintenance Unit.

- Conduct a final walk-through of the project area with the maintenance superintendent or region manager. During the final inspection, update Form MTCE-0023 to reflect changes and corrective actions implemented since the 90 percent construction completion field review with maintenance.

7-104B (3) Stormwater Inspector Responsibilities

The resident engineer may assign an assistant resident engineer as the stormwater inspector. The stormwater inspector will assist the resident engineer in carrying out the work described above, as determined by the resident engineer. Typically, the stormwater inspector will do the following:

- Review and become familiar with the Standard Specifications and project special provisions pertaining to water pollution control.

- Review and become familiar with the authorized WPCP or SWPPP.

- Conduct site inspections. Verify that BMP measures are properly installed and meet the requirements in the Caltrans Stormwater Quality Handbooks and the contract specifications. Look for areas that may require BMP measures that are not deployed or not addressed in the WPCP or SWPPP. Observe and identify any discharges, illicit connections, and illegal discharges. Take photographs of all areas.

- Prepare daily reports on stormwater pollution prevention. Record all stormwater management activities, or inactivity, and conversations with the contractor regarding stormwater pollution prevention.

- Document site visits from regulatory agencies, such as the SWRCB, the RWQCB, or the EPA, and any inspections the agencies perform.

- Monitor the weather reports of the National Weather Service for rainfall predictions. If a rain event greater than 0.5 inch for each event or storm event greater than 0.1 inch in 24 hours is predicted, make sure the contractor prepares a rain event action plan for risk levels 2 and 3 projects and deploys appropriate measures as identified in either the rain event action plan, the SWPPP, or the WPCP.

- Inform the resident engineer immediately of any problems with BMP measures during the implementation of the WPCP or SWPPP and any observed discharges.

- Identify changes in construction that may require amendments to the WPCP or SWPPP, and notify the resident engineer of these findings.

- For sites covered by permits, verify site access and the safety of representatives of regulatory agencies and local agencies when they are on site for any reason.

7-104B (4) Contractor Inspections

The special provisions for water pollution control require the contractor to inspect the construction site at least once a week for the proper implementation, performance, and maintenance of BMP measures identified in the WPCP or SWPPP. The contractor must follow the site inspection procedure specified in the SWPPP or WPCP, and the Construction Site Monitoring Program Guidance Manual. The water pollution control manager, or trained personnel under the supervision of the water pollution control manager, must conduct the site inspections using Form CEM-2030SW, “Stormwater Site Inspection Report.”

The contractor must notify the resident engineer whenever the SWPPP, WPCP, or BMP measures may not reduce or have not reduced the discharge of sediment or other pollutants into a waterway or outside of the project limits. The contractor must follow the verbal notification with a written report using Form CEM‑2061SW, “Notice of Discharge Report,” or Form CEM-2061T, “Notice of Discharge Report—Lake Tahoe Hydrologic Unit Stormwater Sample Field Test Report/Receiving Water Monitoring Report” if applicable. The contractor’s report must conform to the provisions of Section 900.3, “Discharge Reporting,” or Section 50.2, “Discharge Reporting,” of the SWPPP/WPCP Preparation Manual.

If the situation constitutes noncompliance with the permit, the resident engineer must conduct a verification inspection, and if a noncompliance condition exists, report it to the district Construction stormwater coordinator and district NPDES stormwater coordinator. Unless otherwise indicated in the district or regional work plans, the district NPDES stormwater coordinator will report it to the appropriate RWQCB. The resident engineer must require the contractor to amend the WPCP or the SWPPP, if necessary, and to employ additional BMP measures.

7-104B (5) Amendment Review and Processing

During construction, conditions may occur that affect the ability of the contractor to implement the WPCP or SWPPP as initially authorized or the ability of the authorized WPCP or SWPPP to meet the objectives for water pollution control. A change in construction operations or site conditions may result in the discharge of significant quantities of pollutants to surface waters, municipal storm drain systems, or outside of the project limits. The project biologist must be notified of such releases, asked to determine the effect on protected species and their habitats, and asked to determine the need for required notices to regulatory agencies. These changes can include construction staging or schedule changes, staging area modifications, unanticipated offsite drainage effects, and failures of BMPs. The contractor must amend the WPCP or SWPPP if either plan’s effectiveness is diminished by any such changed condition.

Upon the resident engineer’s authorization, the contractor must incorporate all WPCP or SWPPP amendments into the onsite documents. The contractor must prepare WPCP or SWPPP amendments in the format prescribed in the Stormwater Quality Handbooks.

The resident engineer must review the contractor’s proposed revised WPCP or SWPPP amendments for completeness and conformance with the revised conditions, and give written authorization to the contractor if the amendments are acceptable. The authorized revised SWPPP must be uploaded into SMARTS.

7-104B (6) Project Files

The resident engineer must keep copies of all documents related to stormwater pollution prevention in Category 20, “Water Pollution Control Plan or Stormwater Pollution Prevention Plan,” of the project files. Retain the following documents:

- SWPPP or WPCP and all amendments

- Daily reports and photographs related to the prevention of stormwater pollution

- The weekly contractor-prepared Form CEM-2030, "Stormwater Site Inspection Report"

- Forms CEM-2061, "Notice of Discharge Report"

- All correspondence related to stormwater pollution prevention, including notices of noncompliance

- Inspection reports from the district construction stormwater coordinators

- Inspection reports from the resident engineer and assistant resident engineer

- Copies of the certifications required by the specifications

- The printout from SMARTS after filing the Notice of Termination

7-104B (7) Contractor Files

The specifications require the contractor to keep at the project site copies of the SWPPP or WPCP and all authorized amendments.

7-104C Noise Control

Construction and traffic noise may be a sensitive issue in neighborhoods and communities next to state highways. Funding has been provided for highway noise reduction through the construction of sound walls and other noise attenuation. Special restrictions may be employed on night work in sensitive areas, such as residential neighborhoods, schools, and hospitals near the project site. Section 14-8, “Noise and Vibration,” of the Standard Specifications, provides the contractor’s requirements for noise control.

7-105 Permits, Licenses, Agreements, and Certifications

This section covers permits, licenses, agreements, and certifications (PLACs) that may be issued by regulatory agencies or may be part of the contract supplemental project information as described in the special provisions. For assistance regarding PLAC requirements, such as contractor submittals on reporting requirements, protocols, or information training, contact the environmental construction liaison or project biologist.

7-105A Special Use Permits and Other Federal Permits

The Forest Service, Bureau of Land Management, and other federal agencies issue permits to Caltrans to construct and operate highway facilities across lands under their jurisdictions. There can be special use permits, temporary use permits, U.S. Department of Transportation easements, federal land transfers, and, in the case of already existing roadways, there may be prescriptive rights-of-way. In addition, an Archaeological Resources Protection Act permit may be required.

7-105B California Fish and Game Code Sections 1602 and 5650

Section 1602 of the California Fish and Game Code requires that public agencies such as Caltrans reach an agreement with the California Department of Fish and Wildlife (CDFW) if the proposed work affects a waterway. The agreement required by this section of the code is known as the “Lake or Streambed Alteration Agreement,” also known as the “1602 Agreement.” The 1602 Agreement specifically prohibits polluting the waters of the state and may specifically prohibit certain activities at certain times of the year, such as working in the river during spawning season. It may also require the contractor to undertake specific measures, such as installing fish ladders. Violations of the agreement are punishable by fine, imprisonment, or both.

Section 5650 of the Fish and Game Code prohibits placing specified materials in the waters of the state. Violations are punishable by fine, imprisonment, or both. Examples of violations include the following:

- Causing dirt and sediment to enter the waters of the state

- Using creosoted timbers in the waters of the state

- Placing petroleum products, such as asphalt or diesel, into, or where they can get into, the waters of the state

Placing asphalt concrete grindings, chunks, and pieces in areas where they can pass into the waters of the state is also a violation of Section 5650 of the Fish and Game Code. A memorandum of understanding exists between CDFW and Caltrans regarding the placement of asphalt concrete pavement grindings as shoulder backing and the placement of asphalt concrete pieces and chunks in embankments. For a discussion of reusing asphalt concrete as fill material and shoulder backing and a summary of the memorandum of understanding, refer to Index 110.11, “Conservation of Materials and Energy,” of the Highway Design Manual. If a question exists as to whether asphalt concrete grindings or chunks may get into the waters of the state, consult with the environmental construction liaison or project biologist.

7-105C List of Potential Permits, Licenses, Agreements, and Certifications

Table 7-1.1., "State and Local Agency Permits, Licenses, Agreements, and Certifications," lists when permits or approval of contract plans may be required from state or local governmental agencies. The first column lists the activity or a resource affected by construction activity. The second column lists the agency or agencies that may have jurisdiction in the area shown in the first column. The third column indicates the type of permit or plan approval that may be required by the agency or agencies.

Table 7-1.2., "Federal Agency Permits, Licenses, Agreements, and Certifications," lists federal environmental statutes and regulations. The first column lists resources or activities. The second column shows the federal agency having jurisdiction in the area. The third column lists the statute or regulation that applies to the resource or activity.

Most required permits and plan approvals should be obtained during the project’s design phase. However, the following tables may be used as a reminder of the types of permits and plan approvals that may be required when making changes to the original plans. Any changes to plan approvals or PLACs must be coordinated with the environmental construction liaison or Environmental Unit.

Table 7-1.1. State and Local Agency Permits, Licenses, Agreements, and Certifications (1 of 3)

| Resource or Activity | Agency | Permit or Approval |

|---|---|---|

|

Commercial, industrial, and residential development |

Local agency (county or city) |

Land use, general plans, specific plan, conditional use, or subdivision |

|

Conversion of timberland to nonforest uses through timber operations and immediate timberland production zone rezoning |

California Department of Forestry and Fire Protection; California Department of Fish and Wildlife |

Timberland Conversion Permit; |

|

Power transmission lines, pipelines, and railroad crossings |

California Public Utilities Commission |

Review of plans and approval |

|

Solid waste disposal |

Department of Resources Recycling and Recovery (CalRecycle) |

Disposal requirements |

|

Sewage disposal |

County health department |

Disposal requirements |

|

Waste discharge |

State Water Resources Control Board; regional water quality control boards |

Waste discharge requirements |

|

Re-use of soil containing regulated concentrations of aerially deposited lead |

Department of Toxic Substances Control (DTSC) |

Soil Management Agreement for Aerially Deposited Lead-Contaminated Soils (ADL Agreement) |

|

Storing, treating, or disposing of hazardous waste |

Department of Toxic Substances Control |

Caltrans-generated hazardous waste must be sent to a DTSC permitted hazardous waste facility in California |

|

Right-of-way across state parkland |

California Department of Parks and Recreation |

Right-of-way permit, license, easement, joint agreement, or lease |

|

Encroachment on or across a local street or highway |

Local agency (county or city) |

Encroachment permit |

|

Encroachment on 100-year floodplain, intermittent streams, and desert washes |

California Department of Fish and Wildlife |

Lake and Streambed Alteration Agreement (1602 Agreement); California Endangered Species Act (consultation) |

Table 7-1.1. State and Local Agency Permits, Licenses, Agreements, and Certifications (2 of 3)

| Resource or Activity | Agency | Permit or Approval |

|---|---|---|

|

Encroachment on or across cove, bay, or inlet |

California Department of Parks and Recreation, Division of Boating and Waterways |

Review of plans |

|

Air quality |

Air Resources Board or local air pollution control district |

Authority to construct, and permit to operate for activities emitting stationary source pollutants into the atmosphere |

|

Fish and wildlife habitat |

California Department of Fish and Wildlife |

Lake and Streambed Alteration Agreement for activities in lakes, streams, and channels and crossings; California Endangered Species Act |

|

Coastal zone |

California Coastal Commission; local government local coastal program |

Coastal Development Permit; California Coastal Act |

|

Water |

California State Lands Commission; State Water Resources Control Board, Division of Drinking Water; regional water quality control boards; Department of Public Health, the county environmental management department; or local health office |

Land-use lease, such as for encroachments, crossings on tidelands, or submerged lands; National Pollutant Discharge Elimination System Permit for stormwater discharges to surface water; waste discharge requirements for nonstorm discharges to surface water or groundwater to the waters of the state; Permit to Operate a Public Water System |

|

Dredging |

California Department of Fish and Wildlife; State Lands Commission |

Standard or special suction dredging permit; dredging permit |

Table 7-1.1. State and Local Agency Permits, Licenses, Agreements, and Certifications (3 of 3)

| Resource or Activity | Agency | Permit or Approval |

|---|---|---|

|

Surface, such as material borrow sites |

Local agency (county or city) |

Surface Mining and Reclamation Act (SMARA) permit |

|

Burning |

Local air pollution control district; California Department of Forestry and Fire Protection; local fire control agency |

Burn permit |

|

Grading |

Local agency (county or city) |

Grading permit |

|

Entering private property to gather information for temporary use |

Caltrans district Right of Way Unit; |

Property owner approval for temporary encroachment |

|

Entering surface waters to gather information or for construction |

Regional water quality control board |

Water quality certification or waiver |

|

All activities involving dams or reservoirs |

California Department of Water Resources, Division of Safety of Dams |

Approval of plans |

Table 7-1.2. Federal Agency Permits, Licenses, Agreements, and Certifications (1 of 2)

| Resource or Activity | Agency | Federal Statute, Regulation, or Executive Order |

|---|---|---|

|

Water |

Army Corps of Engineers; EPA; Bureau of Reclamation; U.S. Fish and Wildlife Service; National Oceanic and Atmospheric Administration |

Clean Water Act (Section 404) Regulations concerning the National Pollutant Discharge Elimination System (40 CFR); Endangered Species Act |

|

Air |

EPA |

Clean Air Act, Title 42, Sections 7401– 7414 |

|

Fish and Wildlife Habitat |

U.S. Fish and Wildlife Service; Forest Service; National Park Service; National Oceanic and Atmospheric Administration |

Endangered Species Act |

|

Navigable Waters |

Army Corps of Engineers; Coast Guard |

Rivers and Harbor Act |

|

Federal Lands |

Forest Service; Bureau of Land Management; National Park Service; |

Clean Water Act (Section 404); Endangered Species Act |

|

Historic Properties |

Advisory Council on Historic Preservation; State Office of Historic Preservation |

National Historic Preservation Act |

|

Paleontological Resources |

Bureau of Indian Affairs; Bureau of Land Management, Forest Service; National Park Service; Army Corps of Engineers |

Antiquities Act of 1906; Paleontological Resources Preservation Act of 2009; |

|

Coastal Zone |

Army Corps of Engineers; U.S. Fish and Wildlife Service; National Oceanic and Atmospheric Administration |

Biological Opinion for protection of species and habitats; Endangered Species Act; |

Table 7-1.2. Federal Agency Permits, Licenses, Agreements, and Certifications (2 of 2)

| Resource or Activity | Agency | Federal Statute, Regulation, or Executive Order |

|---|---|---|

|

Wild and Scenic Rivers |

National Park Service; Forest Service, Bureau of Land Management |

Code of Federal Regulations, Title 36, Section 297 (36 CFR 297); 43 CFR 8350 |

|

Wetlands |

Army Corps of Engineers; EPA |

Executive Order 11990 (Protection of Wetlands) |

|

Floodplains |

Federal Emergency Management Agency |

Executive Order 11988 (Floodplains Management) |

|

Dredging |

Army Corps of Engineers; U.S. Fish and Wildlife Service; National Oceanic and Atmospheric Administration; Coast Guard |

Clean Water Act (Section 404); Executive Order 11990; Endangered Species Act |

|

Airport Airspace |

Federal Aviation Administration |

Federal Aviation Regulations, Part 77 |

|

Farmland |

Natural Resources Conservation Service |

Farmland Protection Policy Act |

7-106 Hazardous Materials

Many hazardous materials are used in the construction of highway facilities. Employees must take appropriate precautions to minimize their exposure and use protective clothing and equipment. Contractors must submit safety data sheets (SDS) and obtain permission from the resident engineer before bringing any hazardous material onto the job site. For instructions, guidelines, and requirements for handling hazardous materials to assure employee safety, refer to Chapter 16, “Hazardous Materials Communication Program,” of the Caltrans Safety Manual and Chapter 2, “Safety and Traffic,” of this manual. For pesticide use guidelines, refer to Section 4-20, “Landscape,” of this manual.

Key sources of safety data information are available at the website listed in this section. The information this website provides could be critical in the event the contractor fails to provide an SDS or if additional information or clarification is required.

In using this information, keep in mind that the address may change over time and it may be necessary to search the more general website listing or call directly for assistance.

For SDS information, use the following free online database provided by MSDS Catalog Service LLC:

http://msdsdigital.com/msds-database

SDS information may also be obtained by entering the product name followed by SDS in a web search engine.

7-107 Hazardous Waste and Contamination

Hazardous waste may be generated as a result of construction activities. Examples of hazardous waste generating activities include the removal of stripes and pavement markings containing high levels of lead, removing lead-based paint from a bridge or other structure, and excavating soil containing aerially deposited lead. Removing hazardous waste and contamination that has been released into the environment may be part of the project activities. For example, the work may include excavating a defined area of contaminated soil at an old gas station location.

Special permits may be required when generating hazardous waste during construction. For example, demolishing a bridge, whether new, old, or temporary, requires an asbestos survey and a permit from the local air quality management district. For guidance regarding special permit and variance requirements and procedures, contact the environmental construction liaison or district Environmental Unit.

The district Construction division must have a designated district hazardous waste coordinator who will carry out necessary administrative functions for hazardous waste and assist the resident engineer. The coordinator will assist the resident engineer by working with other functional areas in the district and headquarters to do the following:

- Identify hazardous waste training that might be needed

- Make sure of proper notifications if unidentified waste is found during construction

- Provide field personnel with procedures and other information so that the personnel may safely deal with anticipated and unanticipated hazardous waste and contamination

The construction contractor is responsible for making sure that hazardous waste and contamination is managed in compliance with all applicable laws and regulatory requirements. For information about the applicable laws and regulations, refer to Chapter 10, “Hazardous Materials, Hazardous Waste, and Contamination,” of the Standard Environmental Reference, Vol. 1. Additional information regarding hazardous waste management is available at the California Department of Toxic Substances Control (DTSC) website:

For information regarding hazardous waste transportation, refer to the DTSC:

https://dtsc.ca.gov/modes-of-hazardous-waste-transportation/

Section 14-11, “Hazardous Waste and Contamination,” of the Standard Specifications defines the contractor’s responsibilities, including requirements for proper storage and handling. Guidance for resident engineers managing hazardous waste during construction can be found in Chapter 10, “Hazardous Materials, Hazardous Waste, and Contamination,” of the Standard Environmental Reference, Vol. 1, located on Caltrans’ Environmental Analysis webpage.

https://dot.ca.gov/programs/environmental-analysis

Guidance for implementing specific standard special provisions is available on the Environmental Analysis intranet page.

7-107A Contractor-Generated Hazardous Waste Versus Caltrans-Generated Hazardous Waste

Section 14-11, “Hazardous Waste and Contamination,” of the Standard Specifications differentiates between contractor-generated waste and Caltrans-generated waste.

Contractor-generated hazardous wastes are hazardous materials that the contractor brings to the job site that have no further use and must be disposed of. Examples include extra or spent chemicals and waste generated as a result of contractor spills and leaks. Caltrans does not pay for disposal of contractor-generated hazardous wastes. If the contractor-generated hazardous waste is characterized as a federal waste, often referred to as a Resource Conservation and Recovery Act waste, the contractor must obtain an EPA Identification Number from DTSC and sign manifests for disposal. If the contractor-generated hazardous waste is not characterized as a federal waste, it will be characterized as a California hazardous waste—also known as a non-Resource and Recovery Act waste—and the contractor must obtain a state identification from DTSC and sign manifests for disposal.

Caltrans-generated hazardous wastes result from removal of materials that exist within the project limits such as stripes on the highway and soil containing aerially deposited lead. The Standard Specifications requires that Caltrans-generated hazardous waste is labeled consistently, and the resident engineer obtains the EPA temporary generator identification number and signs the hazardous waste manifests. Caltrans-generated hazardous waste is required to be disposed of within California at a facility that holds a DTSC permit to accept the waste. For more information regarding in-state disposal, refer to Chapter 18, “Environmental Contamination” of the Project Development Procedures Manual.

At the preconstruction meeting, have the contractor identify the permitted site for disposal of project hazardous waste. The resident engineer should follow up and confirm the disposal site’s ability to dispose of the waste stream.

During the course of work, the resident engineer must do the following:

- Retain a copy of the manifest. Send a copy to: DTSC Generator Manifests, P.O. Box 400, Sacramento, CA, 95812-0400 within 30 days.

- Review the manifest for accuracy before signing it as the generator. If you identify any errors at the time, line them out, correct them, and initial the correction. If you identify an error after the waste is transported, prepare a manifest correction letter. Seek assistance from the district hazardous waste coordinator if needed. The mailing address on the manifest should be the district office and the manifest should also show the project location address.

- Check that the load is transported by a hauler with a valid hazardous waste hauler certification.

7-107B Aerially Deposited Lead

Aerially deposited lead (ADL) from leaded gasoline emissions still exists in unpaved areas along California highways, and lead is ubiquitous in the environment. Sample and analysis of soil is normally performed during project development to determine whether the lead is present at concentrations requiring special management. Sample results are analyzed statistically. The sampling and analysis methods were developed and are required by the EPA and DTSC. For safety purposes, do not allow Caltrans staff and contractor staff that have not completed a lead safety training program provided by the contractor to work in areas where soil is being disturbed.

7-107B (1) Unregulated Material